A full range of integrated analytical solutions

Contro Valve offers a full range of integrated analytical solutions for process instrumentation, fixed gas detection and environmental monitoring systems from its dedicated facilities located in Brossard QC.

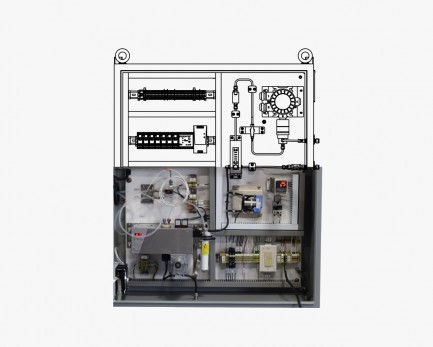

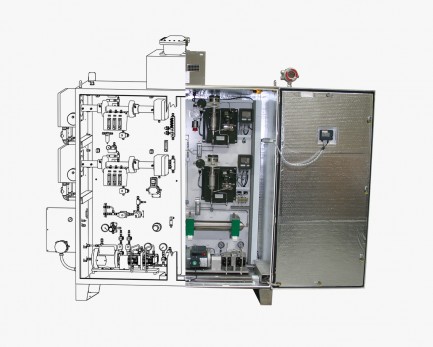

Analytical Integration

These solutions can range from a basic enclosure to safely protect an analytical instrument from the elements to complex systems that could include a large number of process analyzers all connected to a sampling system and equipment for data collection and monitoring. CVE is supported by an extensive list of reputable instrument manufacturers for which the company has trained technicians and engineers to correctly specify, integrate and service these sometimes-complex analytical devices. Our dedication to quality and safety allows us to provide systems that will meet all required conditions for use in hazardous locations.

Through its team of experienced analytical specialists, Contro Valves can provide all the services required to ensure a successful integration project, including:

- Assessment of customer requirements

- Basic system design

- Selection of the main analytical instruments

- Detailed design and shop assembly drawings both in 2D and 3D (Autocad & Solidworks)

- Specification and procurement all required components and materials

- Shop assembly

- Operating manuals

- Pre-operational testing and quality control

- Commissioning and training

These services are supported by Contro Valve’s robust ISO program and vendor qualification process that ensures we meet all customer expectations for quality, reliability and delivery.

Products & Services

Gas Detection and monitoring systems

The safe detection of toxic and explosive gases in industrial environments requires the use of highly reliable gas detection equipment. For situations where there are several gases that require monitoring or where an interface is required to other equipment for their proper protection, a custom monitoring system can be designed that is fully integrated with all the field detection devices. We have the expertise to assemble the equipment, perform the system configuration, calibrate the detectors, and perform end to end testing including verification of all alarm signals.

Emissions Monitoring Systems

For many years now, provincial environmental authorities have established and are enforcing environmental protection standards across Canada. An important part of this initiative is the mandated monitoring requirements to verify that the standards are being met; especially for gaseous emissions into the atmosphere. For many industrial plants, a Continuous Emission Monitoring System (CEMS) is a key component of a plant’s compliance responsibilities.

These regulations cover a number of emissions ranging from the measurement of Highly Reactive Volatile Organic Compounds (HRVOCs) to the monitoring of sulfur emissions, oxides of nitrogen and carbon, and particulate. To assist its customers in meeting these diverse mandated measurements, Contro Valve has the expertise to design a monitoring system for nearly any requirement.

Process Gas/Liquid Analysis and sampling systems

The continuous measurement of the composition of both gas and liquid process streams can be important for both process efficiency, product quality or to satisfy a regulatory requirement. These measurements are generally accomplished through two methods, either by in-situ analysis by installing a sensor in contact with the process or by the extraction of a sample stream from the process and then transporting it to a sampling system before introduction to the process analyzer. Conditions in many manufacturing processes are frequently such that the sample cannot be injected directly into the analytical devices for reasons of temperature, dust loading or humidity. Contro Valve also offers a number of in-situ analyzers for gas and liquid analysis.

Contro Valve designs and manufactures complete analytical systems to meet the most demanding applications. We have the expertise to recommend the correct instruments for the application and to properly integrate them with the sampling system. We have developed systems for many different applications with devices from a number of instrument vendors.

All Contro Valve systems come complete with a Factory Acceptance Test (FAT), CSA approval and required documentation. Our experienced technicians are available to provide on-site installation assistance, start-up and commissioning, and training. Our documentation typically provides all required information to ensure reliable performance of the system and to facilitate its maintenance.

Custom engineered systems for Data logging, communication and industrial automation

Many of the measurement devices that we supply require some type of data acquisition and communication system. Industrial processes often employ multiple data acquisition systems to monitor the health of assets and facility infrastructure. The applications may include level measurement, flow, gas analysis, density and many others. For locations where data is collected from devices in remote locations, the acquisition system can communicate data at certain intervals through cellular communication or similar technologies. Contro Valve’s services include;

- Selection of the main measurement devices

- Design of the cabinet or panel for system integration

- Design of the data acquisition architecture

- Programming of alarms or important inputs and outputs

- Programming and testing of the communication system

- System Assembly

- FAT, Commissioning and start-up

Custom enclosures for instrumentation and industrial equipment

Process instrumentation, piping and valves frequently requires some form of enclosure for the purposes of esthetics, protection from the elements, or to provide controlled climate conditions. In some cases, an “off the shelf” solution from a recognized enclosure manufacturer will meet the customer requirements. In others cases some form of customization will be required. Contro Valve can provide a range of solutions including custom design in three dimensions based on site specific data for each specific location through the use of a 3D camera. This method allows for an extremely accurate design of the enclosure and fit testing prior to fabrication. This approach greatly reduces the need for field modifications at time of installation.

Commissioning, Service and repair of analytical equipment

Contro Valve’s factory trained technicians are well equipped to service and repair a wide variety of analytical devices and systems and have received specific training on the products of the manufacturers that we represent. Our 280 M2 (3,000 ft2) facility in Brossard is set up with test equipment, calibration gases and tools to perform a wide variety of in-shop repairs. A number of our technicians at our other locations across Eastern Canada have also received factory training for the servicing of our main product lines. Additional services include field repair, start-up and training, and emergency support after hours.